Pharmaceutical Packaging

Packing:- Packing consists of enclosing an individual item, or several items, in a container, usually for shipment or delivery. This operation is mostly done by hand and machine.

Pharmaceutical Packaging: Pharmaceutical packaging means the combination of components necessary to contain, preserve, protect & deliver a safe, efficacious drug product, such that at any time point before the expiration date of the drug product, a safe & efficacious dosage form is available.

In the case of medicines, the packaging is a very critical step to the product features, application, and shelf life. The packaging of drugs is important to protect drugs from damage, germs, outer atmosphere, and bacteria and at the same time have to take care of child and old age safety concerns.

As well as being used to store and protect drugs, packaging pharmaceuticals is also essential for identification purposes, for marketing and promoting different brands, and for facilitating the use of pharmaceutical products.

Types of Pharmaceutical Packaging

There are three levels of Pharmaceutical packaging commonly referred to as primary, secondary, and tertiary packaging.

1. Primary packaging system

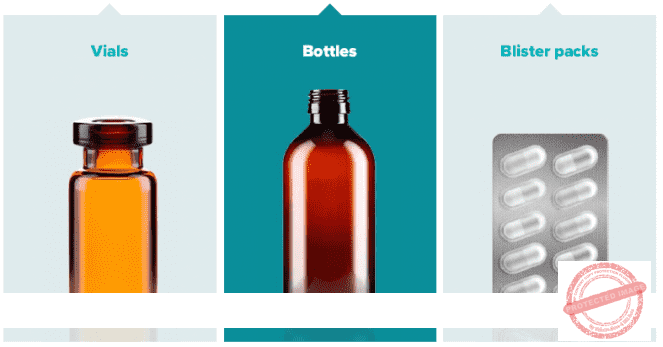

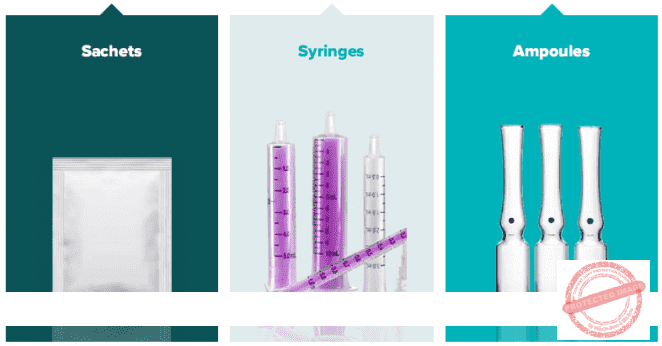

The primary packaging system is the material that first envelops the product and holds it i.e., those package components and subcomponents that actually come in contact with the product, or those that may have a direct effect on the product shelf-life e.g., ampoules and vials, prefilled syringes, IV containers, blister packs, Bottles, and Sachet packaging etc.

2. Secondary packaging system

The secondary packaging system is outside the primary packaging and used to group primary packages together e.g., cartons, boxes, shipping containers, injection trays, etc.

3. Tertiary packaging

A tertiary packaging system is used for bulk handling and shipping e.g., barrel, container, edge protectors, etc.

FUNCTIONS OF PACKAGING

- Product Identification:- Packaging greatly helps in the identification of products.

- Product Protection:- Packaging protects the contents of a product from spoilage, breakage, leakage, etc.

- Facilitating the use of the product:- Packaging should be convenient to open, handle and use for the consumers.

- Information provided to the patient may include:

- Identification no. for dispensing records.

- Name, strength & quantity

- Storage instructions.

- Direction for use.

- Name and address of dispensers.

Types of Packaging materials for Pharmaceutical Packaging

- Glass

- Plastics

- Rubbers

- Paper/cardboards

- Metals

- Closures

Glass

Glass has been widely used as a drug packaging material.

Composition of glass

Glass is mainly made up of Sand/pure silica, Soda-ash (sodium carbonate), Limestone (calcium carbonate) & Cullet (broken glass that is mixed with the batch & acts as a fusion agent for the entire mixture).

The basic structure network of glass is silicon dioxide tetrahedron.

The most common cations found in pharmaceutical glassware are silicone, aluminum, boron, sodium, potassium, calcium, magnesium, zinc & barium. The only anion of consequence is oxygen.

Types of pharmaceutical Glass

Type I – Borosilicate Glass

Type II – Treated Soda-Lime Glass

Type III – Soda-Lime Glass

Type NP – General Purpose Soda-Lime Glass

Type I: Borosilicate Glass

- Composition – 81% – silicon dioxide; about 13% – Boric oxide; & other oxide (Na & Al- non network forming oxide)

- Type –I – Most Highly Chemically resistant inert glass have high hydrolytic resistance due to the presence of Boric oxide & a high melting point due to silicon dioxide.

- Used for all types of preparation whether parenteral preparation or not & for all acid & Alkaline preparation or whether buffered or not.

Type II: Treated Soda-Lime Glass

- Composed of silicon dioxide & high proportional of Sodium oxide (14%) & Calcium oxide (18%).

- Also high hydrolytic resistance.

- Treated with SO2 (“sulfur treatment) & other de-alkalizes to neutralize the interior surface of the container [under controlled temp & humidity] to increase chemical resistance of glass.

- Also known as Soda-lime treated glass

- Used for Acidic & Neutral or pH<7 buffered preparation.

Type III – Regular Soda-Lime Glass

- moderate hydrolytic resistance.

- Used for Non Aqueous Parenteral & powdered for injection preparation

- Containers are untreated

Type IV/NP –Glass

- Used for non-parenteral products, those intended for oral or topical use.

- Container of Type-II & Type-III glass should be used once only

- Glass container are prepared by two method:-

- Blow molding – large vials & bottles (> 100 mL – bottle)

- Drawing from Glass tubing: Upto 100 mL – Ampule & vials

- Advantages of Glass

- They are transparent.

- Essentially chemically inert, impermeable, strong and rigid.

- Does not deteriorate with age

- Variety of sizes and shapes

- Disadvantages of Glass

- Glass is fragile so easily broken.

- Release alkali to aqueous preparation

- Heavy Weight

Plastics

Plastic is one of the most versatile substances in the world. Plastic is light, it’s flexible, it can be used to produce packaging of all shapes and sizes, and it’s very difficult to break. These are all advantages when exploring materials for pharmaceutical packaging.

The drawback of using plastic, rather than glass, is the possibility of plastic materials interacting with the product by means of transferring leachables. There are several different types of plastics used in pharmaceutical packaging, including:

- PET: polyethylene terephthalate

- HDPE: high-density polyethylene

- PP: polypropylene

- Polystyrene

- Polyvinyl chloride (PVC)

Drawback of Plastic:

- Permeation: The transmission of gases, vapors or liquids in either direction through plastic container is known as “Permeation”.

- Leaching: Leaching of constituents from plastic into the product/ Release of a constituent from the plastic material of the container into the formulation is known as “leaching”

- Sorption: Sorption/Absorption of drug molecules/ions on the plastic materials

- Alteration on the properties of plastics or product

METAL

Metals are used for construction of containers. The metals commonly used for this purpose are aluminium ,tin plated steel, stainless steel, tin and lead

Advantages:

- They are impermeable to light, moisture and gases.

- Metals are strong, impermeable to gases & shatterproof, so they are ideal packaging material for pressurized containers

- They are made into rigid unbreakable containers by impact extrusion.

- Form excellent tamper-evident containers

Disadvantages:

- They are expensive.

- They react with certain chemicals

Comments are closed