Evaluation of suspensions

4. Zeta-potential/Electro-Kinetic property

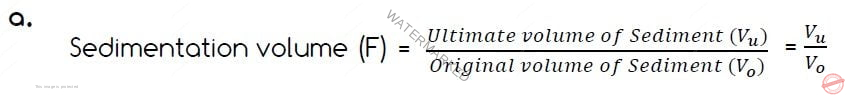

I.Sedimentation volume

- Two parameters are studied for determination of sedimentation.

- Sedimentation volume

- Degree of flocculation

- A most important parameter in the evaluation stability of the suspension.

- Sedimentation volume is a ratio of the ultimate volume of sediment (Vu) to the original volume of sediment (VO) before settling.

- The sedimentation volume gives only a qualitative account of flocculation.

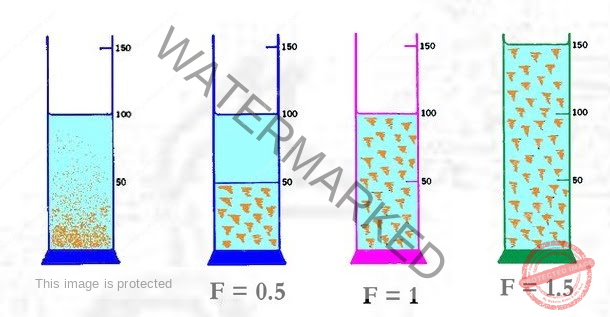

Sedimentation Value: ‘F‘ has values ranging from less than one to greater than one

F= 1 (one)for Ideal suspension;

F=0 (Zero) Complete sedimentation, Totally unstable suspension

Practically, F should be near the value of one.

F>1: i.e Vu > Vo; Sediment volume is greater than the original volume due to the network of flocs formed in the suspension and so loose and fluffy sediment.

F=1: Vu = Vo; The system is in flocculated equilibrium and show no clear supernatant on standing.

F<1: Vu < Vo;

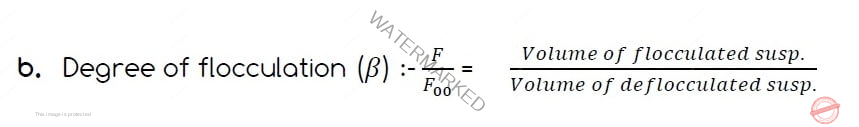

Degree of flocculation (β)

It is the ratio of the sedimentation volume of the flocculated suspension ,F , to the sedimentation volume of the deflocculated suspension, F∞.

The minimum value of β is 1,when flocculated suspension sedimentation volume is equal to the sedimentation volume of deflocculated suspension.

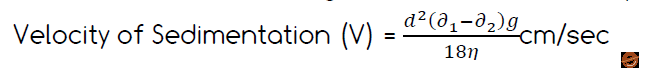

Sedimentation

Settling of solid particles or floccules under gravitation force in liquid at bottom of the container.

The rate of sedimentation is governed by Stock’s Eq.

η= viscosity of external phase

g = gravity acceleration

Stoke’s law

- Limitation of Stoke’ s law

- Particle should be spherical but In suspension irregular

- Particle should settle freely & independently

- Applicatioble For Dilute Suspension: 0.5 to 2% solid w/v-Stokes law applicable

- For Concentration Suspension: 5 to 10% solid w/v- Hindrance occurs- Not Applicable

Stock’s law applicable to only Dilute deflocculated systems where particles settles independently.

How to prevent Sedimentation

-Suspending agents are used to prevent/slow the rate of sedimentation.

-Suspending agents decrease sedimentation by keeping solid particles in suspended in a liquid medium & impart viscosity to the liquid medium.

II. Redispersibility

If a pharmaceutical suspension produces sediment upon storage, it is essential that it should be readily dispersible so that uniformity of dose is assured.

100mL suspension is placed in the graduate cylinder – allowed to settle. After that, the cylinder is rotated at 20 rpm through 360 & when the base of the cylinder is clear of sediment then the endpoint is noted.

Lower the no. of revolution or shorter time for redispersion- Faster dispersibility

Brownian movement: particle size of the suspension is about 2-5 m, they exhibit Brownian movement – No settling occurring.

Brownian movement

If the Particle size of the suspension is about 2-5 micrometer, they exhibit Brownian movement – No settling occurring.

III. Rheological properties

- By “Brook field viscometer” with T-spindle- Behaviour of settling is evaluated &

- Consistency of suspension is evaluated by – cup & bob viscometer & Cone & plate viscometer

IV. Electrokinetics kinetic method

Determination of surface electric charge or Zeta potential of suspension is helpful to find out the stability of the suspension.

It can be determined by observing the movement of droplets under the influence of an electric current (electrophoretic mobility measurements), conjunction with photon correlation spectroscopy.

Join Our WhatsApp Group to receive the latest updates like Pharma Job notifications, study materials, admission alerts, Pharma News, etc

Join Our Telegram Group to receive the latest updates like Pharma Job notifications, study materials, admission alerts, Pharma News, etc

Join Our Telegram Group to Download Free Books & Notes, Previous papers for D.Pharm, B.Pharm, M.Pharm, Drug Inspector & GPAT……….

Comments are closed