- Rheology is the science which deals with flow of the liquid and deformation of the solid.

- The term ‘rheology‘ was derived from the Greek words rheo (flow) and logos (science).

- Viscosity is an expression of the resistance of a fluid to flow: the higher the viscosity, the greater is the resistance.

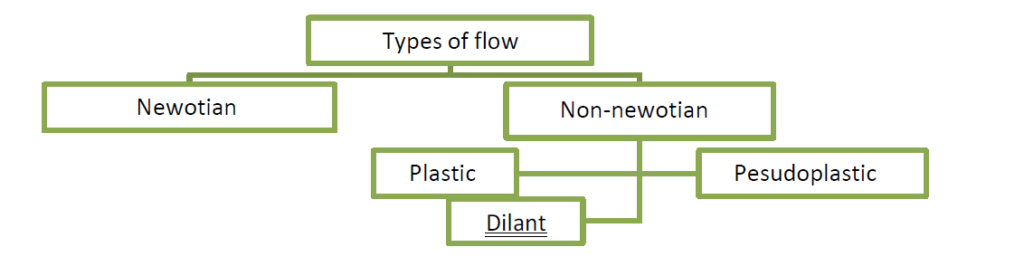

Types of Fluid Flow

1. Newtonian Flow:

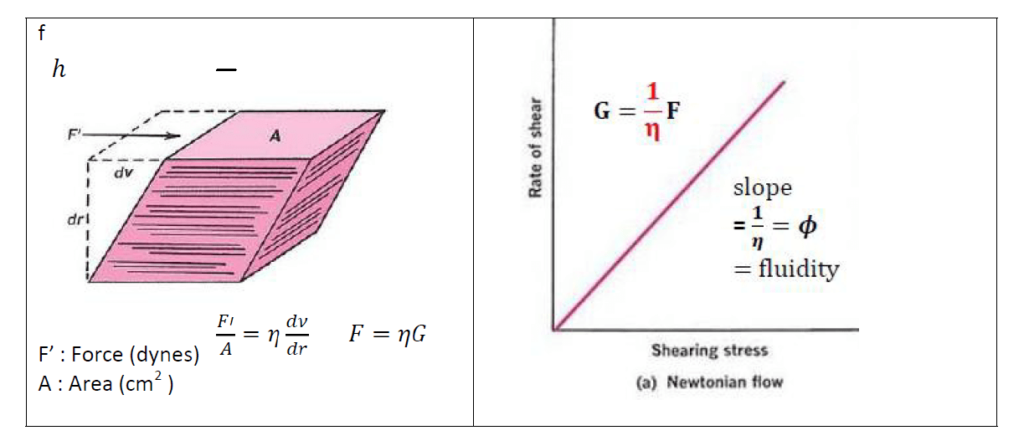

Newton was the first to study the flow properties of liquids in quantitative terms.

Newton’s Law of Flow states that the shear stress between adjacent fluid layers is proportional to the velocity gradient between two layers or shear rate. Liquids that obey Newton’s law of flow are called as Newtonian fluids.

Higher the viscosity of a liquid-greater the force per unit area (shearing stress/F’) required to produce a certain rate of shear (G)

F ∝ G

F= ηG

η= the coefficient of viscosity or simply viscosity or absolute viscosity or dynamic viscosity

F= Force per unit area

G= Rate of shear

Deformation: change of the shape and the size of a matter due to applied forces.

Shear Stress: Force that results in deforming a body divided by the area over which the force is applied.

Viscosity: a parameter that measures resistance to flow

Fluids which obey the Newton’s law of viscosity are called as Newtonian fluids or a fluid whose viscosity does not change with shear rate or a Newtonian fluid is one where there is a linear relationship between shear stress and shear rate.

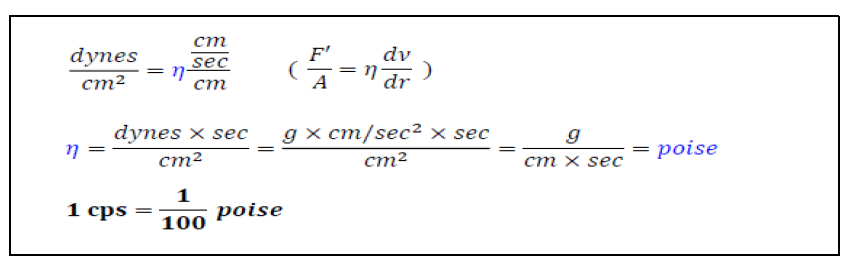

Unit of Viscosity: poise/ centipoise

2. Non-Newtonian flow (Plastic, pseudoplastic and Dilant flow):

- The non-newtonian fluid is observed in the complex heterogeneous system in which the relationship between shear stress(F) and the rate of shear (G) is nonlinear.

- The most liquid in pharmacy or non-Newtonian system. Eg. colloidal solutions, emulsions, liquid suspensions, Creams and ointments.

- Non-Newtonian fluid exhibit three types of Flow

(a) Plastic

(b) Pseudoplastic

(c) Dilatant

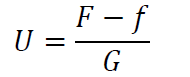

(a) Plastic Flow

Plastic flow curves do not pass through the origin but rather intersect the shearing stress axis (if the straight part of the curve is extrapolated to the axis) at a particular point referred to as the yield value.

The materials that exhibit plastic flow, such materials are known as Bingham bodies.

A Bingham body does not begin to flow until shearing stress corresponding to the yield value is exceeded. At stresses below the yield value, the substance acts as an elastic material.

The slope of the rheogram is termed the mobility, analogous to fluidity in Newtonian systems, and its reciprocal is known as the plastic viscosity, U.

‘f‘ is the yield value, or intercept on the shear stress axis in dynes/cm2. Plastic flow is associated with the presence of flocculated particles in concentrated suspensions.

(b) Pseudoplastic

Pseudoplastic flow is typically exhibited by polymers in solution in contrast to plastic systems, which are composed of flocculated particles in suspension.

The consistency curve for a pseudoplastic material begins at the origin, Therefore, there is no yield value.

The viscosity of a pseudoplastic substance decreases with an increasing rate of shear and this system is known as the shear-thinning system.

Comparison of Newtonian & Now Newtonian flow

Rheogram/consistency curves or flow curves

A rheogram is a plot of shear rate, G, as a function of shear stress, F. Rheograms are also known as consistency curves or flow curves. For this system, the greater the slope of the line, the greater is the fluidity or, conversely, the lower is the viscosity.

| Terms | Unit/discription |

|---|---|

| Viscosity/dynamic viscosity | Unit: Centipoise=0.01poise; g.cm-1.sec-1; Dyne.sec.cm-2; Slop=1/η=Fludity (Ø) |

| Kinematics viscosity/absolute viscosity | =η/d; Unit: Stockes/centistockes; Official in IP (Indian Pharmacopoeia) |

| Relative viscosity | A viscosity of dispersion to that of solvent/vehicle; Example: viscosity of chloroform/viscosity of water |

| Specific viscosity | A relative increase in the viscosity of dispersion over that of solvent alone |

| Reduced viscosity | The ratio of specific viscosity to the concentration |

| Intrinsic viscosity | Concentration =0 (extra plotted at C=0); useful to determine the molecular weight of polymer |

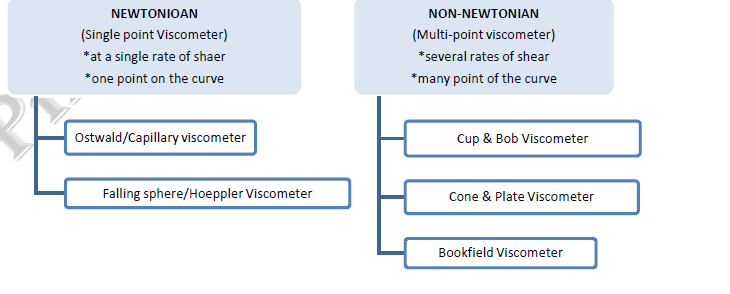

Measurement of Viscosity/ Rheological property

Factor affecting Viscosity

- Intrinsic factor (chemical nature)

- Mw: High Mw-Greater viscosity

- Intermolecular force (cohesive force) -high Greater viscosity

- Shape of molecules: shape- spherical slide easily less viscous

- Symmetry

- Symmetrical- less viscous

- Longer & irregular molecular- more viscous

- Extrinsic factor

- Pressure – cohesive force- increase the viscosity

- Added substance-(sucrose, glycerin, polymers, macromolecular etc)-

- Temperature: High temp. breaking of cohesive force- viscosity ( Exception in gases, with increasing temp, viscosity also increases)

Comments are closed